Heater Agency Approval

Durex offers flexible heating element component recognition for both UL and Canada under UL file number E110394. Durex is continually increasing its product offerings and options under component recognition. Please call Durex for the latest inclusions. In addition, Durex product support can be a valuable resource in seeking approval for UL listing on OEM equipment as it relates to issues with heating elements as Durex has helped many OEMs with certification issues.

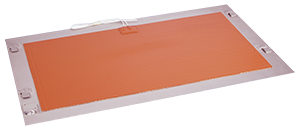

Silicone Heater Specifications

- Sizes: up to 36" wide (consult factory)

- Standard Thickness: 0.030", 0.043", 0.056"

- Maximum Operating Temperature: 400°F (204°C) intermittent

- Minimum Operating Temperature: -60°F (-50°C)

- Maximum Watt Density: 60 watts/in²

- Maximum Voltage: 600 volts

- Wattage Tolerance: standard +5% -10%

Heater Wattage and Voltage

Wattage

Durex can provide silicone rubber heaters with a variety of wattage and power options. Although uniform watt density (watts per square inch) is the most common configuration, Durex engineering can profile the power density to supply the heat where it is needed in the application. A common scenario is when heating a plate, the outer perimeter can be manufactured with a higher watt density to minimize edge loss and yield a more uniform temperature across the surface.

Silicone rubber heaters can also be provided with independent circuits so that two different power densities can be utilized. For example, a higher powered circuit could be used to bring a part up to temperature, while an energy saving lower powered circuit maintains the part at the desired temperature. This design feature can be beneficial for applications that are battery powered to conserve battery life.

Voltage

Durex silicone rubber heaters can be powered with voltages up to 600 volts in both AC and DC applications. For high voltage applications, Durex engineering will select the appropriate materials and design the elements to account for the higher dielectric requirements.

Dual voltage heating elements can also be provided by Durex. A common configuration would be a 120/240 volt heating element. This three wire lead arrangement allows the OEM customer to stock only one heating element that can be utilized in both their 120-volt and 240-volt machines. To accomplish this benefit, Durex engineering designs the heating element with two circuits that can be wired in either parallel or series to achieve the same wattage output for both voltages.

Independent four power lead, dual voltage heaters are also possible under certain situations. For the aerospace and aviation industries, Durex provides 28/120 volt heating elements that contain separate independent circuits to deliver the same wattages for either situation. Consult Durex engineering for assistance with any of these options.

Silicone Heater Attachment Methods

Durex silicone rubber heaters can be attached to customer parts by a variety of methods. Many factors can influence the optimal choice including heater watt density, operation temperature, geometry of part, and part material. Contact Durex engineering to discuss the best method for a specific application.

Factory Vulcanization

Simultaneously with the vulcanization of the two silicone layers for the heating element, Durex can vulcanize (attach) the heating element to the customer's part. Factory vulcanization offers superior heat transfer due to the intimate and consistent bond. Factory vulcanization also offers the customer reduced manufacturing time, thereby increasing production velocity. Depending on part geometry, Durex uses several proprietary vulcanization methods to complete the process.

Pressure Sensitive Adhesive

Durex silicone rubber heaters can be furnished with pressure sensitive adhesives. These heating elements feature a removable liner to protect the adhesive before installation by the customer. Depending on the substrate material and the operating temperature, Durex engineers will select either an acrylic based pressure sensitive adhesive or a silicone based adhesive to best satisfy these requirements. Customer parts should be clean and free from oil and grease before attachment.

Silicone RTV

Durex silicone rubber heaters can also be attached with silicone RTV (room temperature vulcanizing). RTV can achieve a highly reliable bond and is suitable for high temperature operation. Two-part RTV may be required for large heating elements as one-part RTVs require humidity to cure properly. Consult Durex for installation assistance.

Attachments for Removable Heaters

For silicone rubber heaters that need to be easily removed from the part being heated, Durex has available a variety of attachment options. Most any attachment method that is available for fabric can also be utilized on silicone rubber heaters. These include grommets for lacing, grommets with springs and/or buckles, Velcro, Nylon or silicone straps with "D" rings, and straps in conjunction with ITW Nexus style two-part buckles. Consult Durex engineering to discuss the most appropriate option.

Silicone Rubber Heater Temperature Controls

Durex silicone rubber heaters can be designed and manufactured with a variety of temperature controls. Contact Durex engineering to discuss the best method for your specific application.

Thermostats

Durex silicone rubber heaters can be designed and manufactured with a variety of thermostats. Generally, these thermostats provide over temperature (safety) control or temperature control in applications not requiring a tight, precise, temperature control. Durex engineers can achieve a variety of results depending on the thermostat placement. For over temperature protection the thermostat is generally placed over a heated section so that the heating element does not exceed a maximum temperature. By placing the thermostat over a non-heated section of the heating element, the thermostat will primarily monitor the customer part temperature. Durex engineers can increase or decrease the impact of the heating element on the thermostat by increasing or decreasing the size of the non-heated section. Durex engineers can also mount the thermostat so that the sensing side is exposed to open air. This is commonly used in situations where the heating element is located in an electronic enclosure that is exposed to the environment and the heating element is used for condensation prevention or freeze protection.

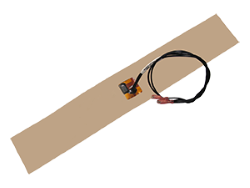

Temperature Sensors

Durex silicone rubber heaters can also be furnished with temperature sensors that provide an electronic temperature control with temperature readings. Most common types are RTDs, thermistors, and thermocouples. These sensors can be mounted over a non-heated section to sense the customer's part temperature or over a heated section to control the temperature of the heating element itself. Because Durex is a manufacturer of temperature sensors as well as a designer of temperature controls, the customer can rely on a greater level of expertise than most flexible heater companies when the complete thermal system is designed.

Thermal Fuses

Thermal fuses are single use devices that can also be incorporated into Durex silicone rubber heaters. These fuses are commonly used as a fail-safe device to assure the shutdown of the flexible heating element in the case where the primary or even secondary control has failed in critical applications. As with the other devices they can be designed and placed over a non-heated section or heated section depending on the desired result. Industry standards recommend an approximate temperature difference of 100°F between the primary temperature control setting and the thermal fuse setting to prevent nuisance tripping and premature aging of the thermal fuse.

Silicone Rubber Lead Wire Options and Harnesses

Durex silicone rubber heaters can be furnished with a variety of lead wire or hook up wire. Typical wire type is Teflon insulated stranded wire. Stranded silicone wire is also often used. Durex silicone rubber heating elements can be supplied with HPN or SJO type cord as well as individual leads that are jacketed in various sleeving. Utilizing both in-house work centers and outside partners, Durex also provides its silicone rubber heaters with a variety of electrical connectors. These options can be as simple as individual terminals to complex multi-pin connectors that combine leads from multi-zoned heating elements and temperature sensors into one housing. This versatility provides Durex's customers with increased value in both production velocity and part number reduction.

Silicone Rubber Heater Thermal Insulation

Durex can provide its flexible silicone rubber heaters with a variety of thermal insulation in varying thickness and material types. For silicone rubber heating elements, silicone sponge form ⅛" to ½" is commonly provided. Kapton® heaters can be provided with silicone or engineered insulations depending on the requirements of the environment. Due to the efficiency of silicone rubber and Kapton heating elements, insulation is most often desired to reduce heating element surface temperature.

Silicone Rubber Heater Construction

Silicone heaters are essentially a vulcanized construction of a low profile etched foil or wire wound resistance element sandwiched between two layers of fiberglass reinforced (or unreinforced) silicone rubber of various thicknesses and constructions.

Etched Foil Elements

Starting with a Durex engineered photo tool, Durex photo develops and then chemically etches a highly precisioned, resistive foil circuit, to be vulcanized internally into a silicone heating element. Durex's silicone etched foil elements can have internal element coverage of greater than 50% of the entire flexible heating element area. This coverage lowers the internal heating element temperature providing longer heater life. Etched foil heaters are superior for high watt density and higher temperature operation. In addition, because the circuit trace width can be varied in the design and manufacturing process, etched foil elements are ideal for distributed watt densities within the same heating element. Durex's efficient production methods result in etched foil being the better choice for low cost, high volume runs of smaller size heating elements.

Wire Wound Elements

Beginning with a computer designed, dedicated, winding pattern and tool, Durex manufactures precision wire wound silicone rubber heaters. Durex engineers select various combinations of resistance wires to be combined or stranded together to produce the optimal result. In many cases the resistance wire is wound around a fiberglass core for added strength and flexibility. Durex's silicone heating elements may incorporate parallel redundant circuits depending on the application and electrical requirements. Wire wound silicone heaters are generally most suited for larger heating elements, low watt densities, and smaller production runs.

Request a quote or contact us for assistance.

Silicone Rubber Heaters Typical Applications

Back to TopAs your direct silicone rubber heater manufacturer, we provide silicone heating elements for a wide range of industries including medical, aerospace, food equipment, industrial equipment, automotive, laboratory, semiconductor, security, and more. Direct applications include, but are not limited to the following:

- Battery warming

- Warming freeze protection

- Autoclaves

- Drum heaters

- Incubators

- Liquid reservoirs

- Optical equipment

- Packaging machinery

- Refrigeration equipment

- Security equipment

- Vacuum chamber

From technology development to product innovation, Durex Industries continues to develop solutions that can be applied to challenging thermal applications.