L-Shaped Square Barrel Heaters Specs & Options

Back to Top

| Cast Materials |

Maximum Operating Temperatures |

| Aluminum 443 |

800°F (427°C) |

| Aluminum 319/356 |

700°F (371°C) |

| Bronze / Copper Alloys |

1400°F (769°C) |

| Iron |

900°F (482°C) |

If required, other cast materials are available.

Cast Processes - Durocast™ perm-mold system uses steel permanent molds. No bake sand system for special castings and short production runs.

Machine Finish - CNC machining is performed for tight tolerances and complex configurations. Milled finishes are provided per specification. Belt sanding, lapping and polishing available to meet application specifications.

Standard Machine Finish Range: 64 to 125 rms.

Fine Finish Per Specifications: 8 to 32 rms.

Standard Flatness: Belt sanded, .015, Milled .005, Lapped, .001

Holes, Cutouts, Thermowells - Mounting or clearance holes, cutouts and thermowells, for inserting temperature measurement probes, cast-in or machined per your specifications.

Inserts - Threaded studs, precision component parts, bushings and special design parts cast acccurately in place.

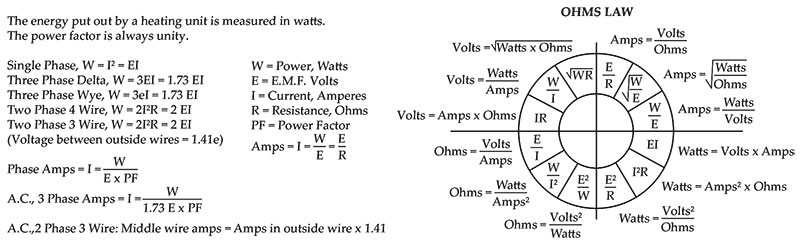

Electrical - Resistance tolerance NEMA standard +10% -%5

| Voltages |

| Element Diameter |

.200 |

.260 |

.315 |

.430 |

.475 |

| Maximum Voltage |

240 |

240 |

277 |

600 |

600 |

Three phase available on large heaters. Maximum watt densities depends on size and application. Consult a Durex Engineer.

UL Component Recognition - DA Series cast in heaters are recognized per file E110394.

Inspection/Testing

- Electrical per UL 499 and UL 1030

- Canadian Standard C22.2 No.72

- Dimensional per specifications using Coordinate Measure Machine

- Quality standard per MIL-Q_9858A

Electrical Data

Cooling Tube Terminations - view images

Type C1 Termination - Plain cooling tube cut to standard 3" length extending from the heater. Specify longer length if required.

Type C2 Termination - 37° Flare nut fitting allows for cooling tube connection to a compression fitting.

Type C3 Termination - Compression fitting mounted directly to cooling tube provides seal for high pressure hook up. Available in standard 3/8 " and 1/2 " NPT. 3/8 " Dia. #55-0010 1/2 " Dia. #55-0011.

Type C4 Termination - Brazed seal with locknut provides an effective seal for high-pressure applications. Mating fittings available upon request.

Type C5 Termination - Brazed angle fitting mounted directly to the cooling tube with right angle 3/8 " FPT as standard. Specify L dimensions.

Type C6 Termination - Cast-in fitting with standard 5/8 " FPT for quick installation of cooling lines with no additional fittings.

Electrical Terminations - view images

Type S Termination - 10-32 threaded screw terminal with a ceramic insulator. Included nuts and washers. Type S standard for cast-in heaters. 6-32, 8-32 and metric sizes also available.

Type A Termination - Right angle terminal block seated on mica washers with 10-32 threaded stud. Included nuts and washers.

Type R Termination - Screw lug terminal seated on mica washers and welded to pin. Includes 8-32 screw for wire connection.

Type D Termination - Quick-disconnect spade lug with 1/4 " blade welded to pin. Other blade sizes available upon request.

Type T Termination - Ceramic insulator with a ceramic top for insulation of electrical connections. Includes complete Type "S" termination with 10-32 threaded stud.

Type HS Termination - Soldered directly to the heating element for moisture-proof termination. 10-32 screw terminal includes nuts and washers. Diameter: .430" - Length: 1 1/8" - Thread: 1/4 - 28, Diameter: .315" - Length: 1 3/8" - Thread: 10 - 32, Diameter: .250" - Length: 1 5/8" - Thread: 8 – 32

Type P Termination - Plain pin for field attachment of termination. Pin length is 1/2 " standard.

Type L Termination - Terminal lug with 10-32 screw is welded directly to the heater pin. Can be oriented straight or at a right angle.

Type C Termination - Flexible armor cable for abrasion resistance with a high temperature lead wire attached to the heating element. Specify L dimension when ordering.

Cast Heater Protective Housing - view images

Type B1 Housing - Explosion proof cast iron housing with 1/2 " NPT double hub. Single phase design shown. Larger housing for 3 phase design also available.

Type B2 Housing - Explosion proof cast iron housing with 1/2 " NPT single hub. Single phase design shown. Larger housing for 3 phase design also available.

Type B3 Housing - Standard size stainless steel sheet metal box with two 1/2 " electrical knockouts. Other sizes and types available.

Type B4 Housing - Stainless steel terminal enclosure with male ERGE plug mounted on top. Mating connections available upon request.

Type B5 Housing - Die cast aluminum enclosure with 1/2 " or 3/4 " threaded electrical connections mounted to vented cooling tower. Other sizes and types available for single and 3 phase designs.

Type B6 Housing - Explosion resistant box with 1/2 " NPT single hub, designed for low profile applications. Single phase only. Different hub configurations are available.

Cast In Heater Special Services

- Radiograph (X-ray): Confirmation of internal element configuration and casting soundness available through x-ray.

- Plating/Coating: Electroless nickel plating, anodize, teflon® coatings and special blasted surfaces are available per customer specifications.

- Pressure Testing: High pressure leakage testing is done in-house per application requirements.

- Heat Treating: Stress relieving and aging through heat treating available as required.

- CMM Inspection: Coordinate Measuring Machine used for precision quality control of tight tolerance machining requirements.

- Helium Leak: Detect microleakage from casting body.

- Temperature Uniformity: Conform heat uniformity across the finished surface.

- Class 1000 Clean Room: Clean room assembly and packaging per class 1000 standards.

- Solidworks 3D Modeling: Engineering software provides 3D models of proposed or existing product designs.

- Custom Packaging: Customer specific packaging for delicate surfaces, large multi-product shipments, or long term storage.

- Life Cycle Testing: Life cycle test chamber for longterm testing of uniformity and performance characteristics.

- Material Certification: Precise records and certifications on materials which require traceability to specific standards.

- Sensor Calibration: NIST traceable calibration lab for calibration and certification of any temperature sensor requirements.

- FEA Analysis: Preview of proposed design constructions using FEA analysis.

Installation & Maintenance Guidelines for Cast Heaters

- Always ensure that cast-in heaters are properly mounted to the application to avoid warping of flat heaters or "walking" of barrel heaters. After the initial start-up, retighten the heater mounting system to assure complete surface contact. Periodically check the bolts or straps and tighten as required maintenance.

- Tighten all liquid cool connections securely to avoid rupture from internal steam pressures. Cast in C6 fittings or brazed connections are the most reliable. Properly maintain these connections to avoid leaks that will destroy the heater. Do not operate heating and cooling simultaneously to avoid thermal shock of the cooling tubes.

- It is recommended that water used for liquid cooling applications be treated to avoid corrosion and hard water deposits that will clog the cooling tubes over time.

- Install proper temperature control prior to operation of the heaters to ensure protection from over-temp situations which may damage the heater or equipment. Periodically changing temperature sensors is good preventive maintenance.

- Electrical terminals must be properly insulated and made tightly to ensure safe operation. All heater installations must be properly grounded. All electrical terminations must be made per applicable Electrical Safety Codes and O.S.H.A. regulations.

- Do not operate the heaters outside of the voltage and temperature of the design. This will cause the heaters to fail.

- ALWAYS disconnect the electrical power to heaters prior to service.