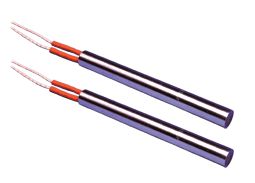

Cartridge Heaters

Electric cartridge heaters offer a swaged design for high watt density, high temperature, and long service life applications. High performance custom designed cartridge heaters are critical to minimizing equipment downtime and maintenance costs. By utilizing our state-of-the-art design software and diverse engineering expertise, Durex Industries provides a wide range of custom cartridge heating element design and manufacturing capabilities. We manufacture and design industrial cartridge heaters that can with stand high temperatures up to 1400°F (760°C).

Cartridge Heating Elements For Efficient Heat Transfer

Cartridge heaters feature a compact, swaged construction design that resists shock and vibration while providing highly efficient heat transfers and maximum heater element life. Whether for use in dies, platens, or molds, or for liquid immersion applications, cartridge heating elements are ideal solutions to provide pinpoint, high efficiency heating.

Durex cartridge heaters last up to 20 times longer than uncompacted heating elements. We also provides UL/cUL component recognition upon request, with additional design concepts that can be custom manufactured to meet your exact specifications.

Cartridge Heater Element Design Features & Benefits

Durex’s custom cartridge heating elements provide the following beneficial design features:

- Nichrome 80-20 Resistance wire for long life, high temperature performance

- Highly compacted unit provides high dielectric strength and excellent heat transfer

- Standard diameters from 1/8” to 1” diameter sizes to fit virtually every application

- Standard 304SS and Incoloy 840 Alloy sheaths available

- Shock and vibration resistance

- Internal thermocouple sensor available in most configurations

- Up to 480V with UL/cUL component recognition, higher Voltages possible

Contact Durex Industries for Custom Electric Cartridge Heaters Today

Contact us for more information regarding our custom electric cartridge heaters, or call us at 800-739-9060 and we will gladly answer any questions that you may have. Durex Industries is your trusted manufacturer of industrial cartridge heating elements.

Cartridge Heaters Specs & Options

Back to Top| Nominal Diameter | 1/8" | 1/4" | 5/16" | 3/8" | 1/2" | 5/8" | 11/16" | 3/4" | 1" | 6.5mm | 8mm | 10mm | 12.5mm | 16mm | 20mm |

| Actual Diameter 0.002" (0.05") | 0.122 | 0.246 | 0.309 | 0.371 | 0.496 | 0.621 | 0.683 | 0.746 | 0.996 | 0.252 | 0.312 | 0.391 | 0.489 | 0.627 | 0.784 |

| Maximum Voltage | 240 | 240 | 240 | 240 | 480 | 480 | 480 | 480 | 480 | 240 | 240 | 240 | 480 | 480 | 480 |

| Maximum Amps | 3.1 | 4.2 | 6 | 6.5 | 10.5 | 22 | 22 | 22 | 25 | 4 | 6 | 6 | 10.5 | 22 | 22 |

| Minimum Wattage | Consult Durex Industries for minimum wattage | ||||||||||||||

| Wattage Tolerance | +5, -10% of rated wattage | ||||||||||||||

| Length Tolerance | 2% of length, 3/32" minimum | ||||||||||||||

| Camber Tolerance | Up to 12" long: .010" per foot Over 12" long: .015" per foot | ||||||||||||||

| Watt Density | Total wattage divided by diameter x 3.14 x heated length | ||||||||||||||

Termination Types

Standard Leads - Fiberglass insulated lead wires are externally connected to nickel pins. The connection area is electrically insulated with heavy-wall fiberglass sleeving. 12" leads are standard. Specify longer leads if required. Standard cold length at lead exit: 0.375". Standard cold length at disc end: 0.25".

Standard Leads - Fiberglass insulated lead wires are externally connected to nickel pins. The connection area is electrically insulated with heavy-wall fiberglass sleeving. 12" leads are standard. Specify longer leads if required. Standard cold length at lead exit: 0.375". Standard cold length at disc end: 0.25".

Swaged Flexible Leads - Fiberglass insulated lead wires are internally connected to nickel pins. This design allows for much greater flexibility at the lead exit point from the heater. 12" Leads are standard. Specify longer leads if required. Standard cold length at lead exit: 0.375". Standard cold length at disc end: 0.25"

Swaged Flexible Leads - Fiberglass insulated lead wires are internally connected to nickel pins. This design allows for much greater flexibility at the lead exit point from the heater. 12" Leads are standard. Specify longer leads if required. Standard cold length at lead exit: 0.375". Standard cold length at disc end: 0.25" Teflon Leads & Seals - Teflon® insulated lead wires with Teflon® end seal swaged into the cartridge heater sheath provides a superior moisture and chemical resistance. This design requires at least a 1" cold section at the lead exit end of the heater. 12" Leads are standard. Specify longer leads if required. Specify "E" for epoxy potted end seal with 12" Teflon® insulated leads.

Teflon Leads & Seals - Teflon® insulated lead wires with Teflon® end seal swaged into the cartridge heater sheath provides a superior moisture and chemical resistance. This design requires at least a 1" cold section at the lead exit end of the heater. 12" Leads are standard. Specify longer leads if required. Specify "E" for epoxy potted end seal with 12" Teflon® insulated leads. Right Angle Leads - Fiberglass insulated leads exit the cartridge heater sheath at a right angle for easier access and routing. Includes stainless steel end cap and high-temperature potting. Specify the overall length of the cartridge heater.

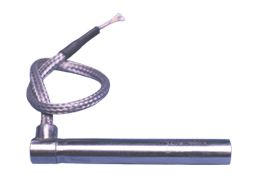

Right Angle Leads - Fiberglass insulated leads exit the cartridge heater sheath at a right angle for easier access and routing. Includes stainless steel end cap and high-temperature potting. Specify the overall length of the cartridge heater. Straight Braid Leads - Stainless steel braid over fiberglass insulated lead wires exits straight from cartridge heater sheath for abrasion resistance, yet is flexible enough for sharp bends. 3" additional lead beyond braid is standard. Specify longer lead if required. Standard cold length at lead exit: 0.375". Standard cold length at disc end: 0.25"

Straight Braid Leads - Stainless steel braid over fiberglass insulated lead wires exits straight from cartridge heater sheath for abrasion resistance, yet is flexible enough for sharp bends. 3" additional lead beyond braid is standard. Specify longer lead if required. Standard cold length at lead exit: 0.375". Standard cold length at disc end: 0.25" Right Angle Braid Leads - Stainless steel braid over fiberglass insulated lead wires exits at a right angle from cartridge heater sheath. Includes stainless steel end cap. 3" lead beyond braid is standard. Specify longer lead if required. Specify overall heater length when ordering.

Right Angle Braid Leads - Stainless steel braid over fiberglass insulated lead wires exits at a right angle from cartridge heater sheath. Includes stainless steel end cap. 3" lead beyond braid is standard. Specify longer lead if required. Specify overall heater length when ordering.

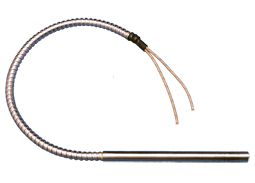

Straight Armor Cable Leads - Armor cable over fiberglass insulated lead wire exits straight from cartridge heater sheath for heavy duty lead protection. 3" lead beyond armor is standard. Specify longer lead if required. Specify galvanized or stainless steel armor when ordering.

Straight Armor Cable Leads - Armor cable over fiberglass insulated lead wire exits straight from cartridge heater sheath for heavy duty lead protection. 3" lead beyond armor is standard. Specify longer lead if required. Specify galvanized or stainless steel armor when ordering.

Right Angle Armor Cable - Stainless steel flexible armor cable over fiberglass insulated lead wires exits at a right angle from cartridge heater sheath. Includes stainless steel cap. Galvanized or stainless steel armor. 3" lead beyond armor is standard. Specify longer leads if required. Specify galvanized or stainless steel armor and overall cartridge heater length.

Right Angle Armor Cable - Stainless steel flexible armor cable over fiberglass insulated lead wires exits at a right angle from cartridge heater sheath. Includes stainless steel cap. Galvanized or stainless steel armor. 3" lead beyond armor is standard. Specify longer leads if required. Specify galvanized or stainless steel armor and overall cartridge heater length.

Right Angle Armor Cable With Copper Elbow - Armor cable leads extend at a right angle from cartridge heater with right angle copper elbow. 3" lead beyond armor is standard. Specify longer leads if required. Specify galvanized or stainless steel armor and length of cartridge heater sheath. Note: For Galvanized armor add "G" as a suffix to termination number.

Right Angle Armor Cable With Copper Elbow - Armor cable leads extend at a right angle from cartridge heater with right angle copper elbow. 3" lead beyond armor is standard. Specify longer leads if required. Specify galvanized or stainless steel armor and length of cartridge heater sheath. Note: For Galvanized armor add "G" as a suffix to termination number.

Internal Thermocouple - The thermocouple provides an integral method for temperature control. Thermocouple junction (grounded or ungrounded) can be located at the end disc, center, or lead end. Please specify thermocouple type, location, and whether grounded or ungrounded. Type J or Type K is standard. Other thermocouple types are available.

Internal Thermocouple - The thermocouple provides an integral method for temperature control. Thermocouple junction (grounded or ungrounded) can be located at the end disc, center, or lead end. Please specify thermocouple type, location, and whether grounded or ungrounded. Type J or Type K is standard. Other thermocouple types are available.

Immersion Pipe Fitting - Threaded NPT pipe fitting is silver soldered or welded directly to cartridge heater sheath for immersion applications, available in stainless steel or brass. Fiberglass insulated lead wires exit high-temperature cement potting. 3/4" cold required before fitting. Epoxy & Epoxylite® available for moisture applications. Other lead options are available.

Immersion Pipe Fitting - Threaded NPT pipe fitting is silver soldered or welded directly to cartridge heater sheath for immersion applications, available in stainless steel or brass. Fiberglass insulated lead wires exit high-temperature cement potting. 3/4" cold required before fitting. Epoxy & Epoxylite® available for moisture applications. Other lead options are available.

Post Terminals - Threaded stainless steel terminals are welded directly to nickel pin for rigid mount applications. Includes two (2) nuts and washers for each terminal.

Post Terminals - Threaded stainless steel terminals are welded directly to nickel pin for rigid mount applications. Includes two (2) nuts and washers for each terminal.

Mounting Flange - Stainless steel flange welded directly to cartridge heater sheath. Fiberglass insulated lead wires are standard. Other flange sizes and hole patterns are available upon request.

Mounting Flange - Stainless steel flange welded directly to cartridge heater sheath. Fiberglass insulated lead wires are standard. Other flange sizes and hole patterns are available upon request.

Duraslik- Cartridge Heater Non-Stick Coating

The Duraslik non-stick coating eliminates the need for additional release agents to be applied to the cartridge heater prior to the insertion. The non-stick coating acts as a corrosion inhibitor and a solid lubricant on the inner diameter of the drilled hole when the heater is energized, allowing for reduced downtime caused by "sticky" heaters during replacement.

Benefits:

- Reduced downtime caused by "sticky" heater removal

- Coating is bonded directly to the heater sheath for easy handling

- No need for secondary release agents prior to insertion

- Superior heater transfer characteristics for increased life

Technical Data:

- The ultra-thin Duraslik coating only adds 0.0010" to 0.0015" (0.025 - 0.037mm) to the cartridge heater diameter

- Coating is applied up to 1/4" of lead exit

- Coating is rated up to 1400°F (760°C)

- Heater diameter is manufactured to within standard tolerances after the coating is applied

Special Modifications

In addition to the standard design, Durex Industries offers a variety of special modifications which are available to customize the heater for your application.

- Distributed Wattage: Resistance windings can be concentrated in specific areas of the heater for localized heat distribution.

- Centerless Grinding: Precision grinding of the heater sheath provides tighter diameter tolerances when required.

- DURASLIK Coating: Duraslik coating can be provided on heater sheath for applications requiring chemical resistance or easy removal.

- Ground Leadwire: Separate color coded ground wire can be provided when required.

- Special Connectors: Various connectors for power leads can be provided upon request.

- Terminal Boxes: NEMA 1, as well as moisture resistant or explosive resistant boxes, can be provided when required.

- Do not exceed recommended maximum watt density specified for the heater size.

- The cartridge heater sheath must fit properly into the machined hole, a tight fit is crucial.

- Protect the heater from contaminates such as oil, grease, and vapors.

- Install adequate KW to accomplish workload and make up for heat losses.

- Store cartridge heaters in a dry area, especially during periods of high humidity.

- Protect leads from abrasion, abuse, and exposure to contaminants such as grease and plastic drool.

- Maintain temperature control and keep accessories in good working condition to obtain correct operating conditions.

- All cartridge heaters have hygroscopic tendencies and can accumulate moisture in shipping and storage. Heaters with low dielectric insulation values (less than 1 megohm) can be baked in an oven for several hours or started at low voltage to eliminate moisture.

Cartridge Heaters How to Order

Back to Top- Quantity

- Nominal Diameter - see specifications for assistance

- Overall Sheath Length - measured in inches or millimeters from end to end of heater sheath

- Lead Length - specify in inches

- Termination Type - see terminations

- Voltage - specify

- Wattage - specify

- Other Custom Specifications - specify as required

Cartridge Heaters Typical Applications

Back to Top- Liquid Immersion

- Plastic Molds

- Dies

- Labeling

- Medical Equipment

- Platens

- Packaging Equipment

- Hot Stamping

- Sealing

- Injection Molding

Cartridge Heaters Case Studies

Back to TopCustom Cartridge Heaters For Beverage Manufacturing

Cartridge Heaters For Heat Seal Packaging Equipment

Electric Cartridge Heaters For Plastic Parts Manufacturing

1/8" Cartridge Heaters For Analytical Instrumentation

Cartridge Heaters Literature Downloads

Back to TopCartridge Heaters 6-22-23 - 2MB

Standard Cartridge Heater Parts List 6-22-23 - 1MB