Temperature Control & Sensing Options

Over the Side Tank Heaters With Thermostats

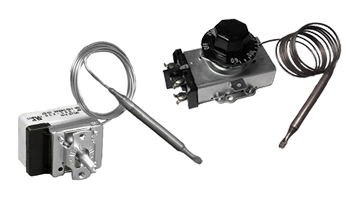

Thermostats can be mounted inside of the terminal enclosure to provide an inexpensive, local temperature control of the heater and liquid being heated. Process (automatic control) and high limit (manual reset) thermostats are available. Temperature settings are adjustable unless a fixed set point thermostat is ordered. Single pole (SPST) thermostats are typically used for single phase heaters and double pole (DPST) thermostats for three phase heaters. For high current draw heaters, the thermostats are often wired for "pilot duty" to a user-supplied relay.

When ordering, please specify temperature range, the number of poles, the type of thermostat (process, manual reset or high limit), and if it will be used directly or wired for pilot duty.

Standard available bulb & capillary thermostats

| Temperature Range |

Type |

Maximum Amps to 240VAC |

Maximum Amps to 480V |

| 0 - 100°F |

Single Pole (SPST) |

25 Amps |

N/A |

| 85 - 230°F |

Single Pole (SPST) |

25 Amps |

N/A |

| 120 - 570°F |

Single Pole (SPST) |

25 Amps |

N/A |

| 0 - 100°F |

Double Pole (DPST) |

30 Amps |

21 Amps |

| 60 - 250°F |

Double Pole (DPST) |

30 Amps |

21 Amps |

| 100 - 250°F |

Double Pole (DPST) |

30 Amps |

21 Amps |

Over The Side Heaters With Temperature Sensors

A process thermocouple or RTD probe can be inserted into a thermowell to measure process fluid temperature and provide control input to an external controller. Type J and Type K thermocouples are the most common calibrations, but RTDs and other calibrations are available. A high limit thermocouple can be welded or clamped to a heater element to measure element temperature in order to prevent overheat conditions.

Immersion Tank Heaters With Temperature Control Panels

Durex Industries electrical temperature control panels meet a wide variety of industrial requirements by providing an extensive line of standard and custom engineered solutions. All temperature control panels are fully pre-wired and tested at the factory and come with a set of drawings including schematics and installation and maintenance manuals. Standard temperature control panels include NEMA 12 enclosure, main power disconnect, process temperature controller, pilot lights, panel labels, primary and secondary fusing, and ventilation fan /filter (if required). Other options available.

Durex Industries electrical temperature control panels meet a wide variety of industrial requirements by providing an extensive line of standard and custom engineered solutions. All temperature control panels are fully pre-wired and tested at the factory and come with a set of drawings including schematics and installation and maintenance manuals. Standard temperature control panels include NEMA 12 enclosure, main power disconnect, process temperature controller, pilot lights, panel labels, primary and secondary fusing, and ventilation fan /filter (if required). Other options available.

Heater Construction Options

Voltage and Wattage - Standard design units are shown on the Standard Heaters tab. However, volts, watts, and watt density can be modified to suit application requirements. Contact Durex for more information.

Sheath Material - Steel, 304SS and Incoloy® 840 are standard materials, but others such as Incoloy® 800, 316SS, 321SS, etc. are available as well.

Riser - Standard design heaters use a junction box and riser pipe assembly. This can be varied to suit application needs. Also, depending on configuration, the riser assembly can be eliminated and the heater elements (with a long cold riser section) terminated in the enclosure or in a mounting flange.

Mounting Flange and Manhole Cover - For a more permanent tank installation, heaters can be fabricated with a mounting flange or manhole cover plate in order to be seated and secured to the tank. Contact Durex for more information.

Sludge Legs - Four-inch high sludge legs are standard on heaters unless otherwise specified. Sludge legs are not required if the heater will be mounted onto the tank with a mounting clip or flange that ensures that the heater elements remain at least 4" off the tank bottom.

Sheath Treatment and Finish - Passivation and electropolish if wetted parts can be provided to remove any free iron and also provide a smoother surface finish. Contact Durex for more information.

Seal Options - Standard design heaters us an epoxy seal for moisture protection. RTV is an optional seal if this is preferred to an epoxy seal.

To place an order, or get a quotation, please provide the information itemized below. Contact Durex Industries for further assistance.

- Quantity

- Heater Type - Type 'LN' (L-shaped) or Type 'ON' (O-shaped) or another custom configuration.

- Electrical Rating - Voltage, phase, wattage.

- Element Sheath and Riser Material - Steel, 304SS, Incoloy® 840 or other material.

- Element Watt Density - 8, 16, 23, or 48 W/in² or other value.

- Riser Height - Provide the distance from bottom of the heater bundle or junction box to the enclosure.

- Immersion Bundle Length - Provide desired (or maximum allowable) length.

- Seal Options - Epoxy is standard, specify RTV or other if required.

- Electrical Enclosure - NEMA 4 is standard. NEMA 7 and 4/7 are available as well as hazardous location certified enclosures.

- Mounting Clip or Flange - Indicate clip or flange location on riser relative to the heater bundle and provide clip or flange specifications.

- Sensing and Control - None (standard), thermostat type (process or high limit manual reset) and range; process sensor type and/or high limit sensor type.

Over The Side Immersion Literature Downloads

Back to TopProcess Heater Brochure PROC-BROC-0912- 7MB