Pipe Insert (Drywell) Heaters Specs & Options

Back to TopHeater Specifications

Refer to the Screw Plug Immersion or Flange Immersion heater sections for heater descriptions, technical and ordering information. Heater watt densities are limited to 8 W/in2 for standard designs, however, other watt densities may be recommended based on application requirements.

Mounting and Installation Orientation

Pipe insert dry well heaters are usually horizontally mounted into the side of a tank. Due to space or access limitations, this style heater can be installed vertically as well. If a vertical installation is likely required, please contact Durex to discuss the specific application and design requirements prior to ordering.

Control and Temperature Sensing Options

Pipe insert dry well heaters are typically remotely controlled by either a thermostat or thermocouple (or RTD) mounted in the tank. However, Durex always recommends the use of a high limit heater element thermocouple to monitor internal temperatures to ensure long heater life and also to provide possible early detection of system upset.

Temperature Control Panels for Pipe Insert Heaters

Durex Industries electrical temperature control panels meet a wide variety of industrial requirements by providing an extensive line of standard and custom engineered solutions. All temperature control panels are fully pre-wired and tested at the factory and come with a set of drawings including schematics and installation and maintenance manuals. Standard temperature control panels include NEMA 12 enclosure, main power disconnect, process temperature controller, pilot lights, panel labels, primary and secondary fusing, and ventilation fan /filter (if required). Other options available.

Durex Industries electrical temperature control panels meet a wide variety of industrial requirements by providing an extensive line of standard and custom engineered solutions. All temperature control panels are fully pre-wired and tested at the factory and come with a set of drawings including schematics and installation and maintenance manuals. Standard temperature control panels include NEMA 12 enclosure, main power disconnect, process temperature controller, pilot lights, panel labels, primary and secondary fusing, and ventilation fan /filter (if required). Other options available.

Construction Options

Custom Voltage and Power Rating

A large variety of standard design heaters are available, however, custom volts, watts and watt density are available upon request. For reference, screw plug dry well heaters are typically used up to 5kW. A tank needing 15kW, for example, would use three 5kW heaters. Larger power requirements will need flange immersion pipe insert heaters in order to provide the necessary kW.

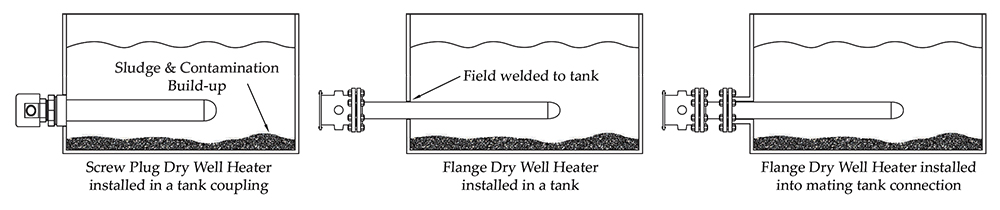

Mounting Fitting and Configuration

Pipe insert dry well heaters can be designed and manufactured for direct field welding to an existing tank. If a fitting is required for mating to a tank coupling or flange, a screw plug (or flange) can be welded to the dry well pipe to allow for mounting to the tank. The tank mount fitting size is generally (but not always) one size larger than the heater screw plug (or flange) size. For example, a 2" to 2 ½" NPT pipe coupling would be supplied on the dry well. This enables the pipe insert to be screwed into the storage tank coupling and the 2" NPT screw plug heater to be mounted into the dry well pipe assembly.

Pipe Insert (Dry Well) Vessel Materials

Standard dry well material is carbon steel. However, other materials such as 304SS, 316SS and Inconel® 600 are available.

Pipe Insert (Dry Well) Exterior Treatment and Finish

Passivation and electropolish of the pipe insert external surface can be provided to remove any free iron and also provide a smoother surface finish.

To place an order, or get a quotation, please provide the information itemized below.

Contact Durex Industries for further assistance.

- Quantity

- Electrical Rating: Voltage, phase, Wattage

- Heater Plug or Flange Size: If known or required, the specific heater screw plug or flange size and material

- Mounting Fitting to Tank: None (for direct-to-tank weld in units), screw plug or flange size and material

- Dry Well Information: Well dimensional details and/or constraints and material requirements

- Electrical Enclosure: NEMA 1(standard), NEMA 4, NEMA 7, NEMA 4/7 or CSA Certified.

- Please designate hazardous location information if a certified enclosure is required

- Sensing and Control: None (standard) or high limit temperature sensor type

Request QuotePipe Insert (Drywell) Heaters Literature Downloads

Back to TopProcess Heater Brochure PROC-BROC-0912- 7MB

Drywell Heaters