Industrial Flange Immersion Heaters

Durex Industries manufactures electric flange immersion heaters for industrial and process heating applications, providing economical and reliable heating for large volume, high power and/or high-pressure applications and for use in smaller pieces of equipment such as boilers and chillers.

Industry Standard or Custom Designed Flanged Immersion Heaters

Process immersion flange heaters are constructed of hairpin bent tubular heating elements brazed or welded onto ANSI standard flanges or plate flanges of various shapes and sizes.

Flanged Heater Design Features:

- Standard or custom designs

- Pressurized or non-pressurized applications

- ANSI 3” to 14” flanges readily available, up to 48” possible

- ANSI Class 150lb and 300lb ratings readily available, up to 2500lb possible

- ASME Section VIII Div 1 “U” Partial Stamp to 3,000 psig

- Power ratings from 1kW to well over 1MW

- Flange materials: steel, 304 and 316 stainless steel

- Sheath materials: steel, copper, 304 and 316 stainless steel, Incoloy 840 and 800, Inconels

- C-UL recognized heater elements available

- Up to 600VAC rating

- NEMA 1, NEMA 4 light duty, and CSA certified Class 1, Div 1 terminal enclosures available

- Integral thermostats or thermocouples for temperature control and sensing

Parts List for Industry Standard Designed Flanged Immersion Heaters

3" Flanged Immersion Heaters with NEMA 1 Enclosure and no Thermostat

4" Flanged Immersion Heaters with NEMA 1 Enclosure and no Thermostat

5" Flanged Immersion Heaters with NEMA 1 Enclosure and no Thermostat

6" Flanged Immersion Heaters with NEMA 1 Enclosure and no Thermostat

8" Flanged Immersion Heaters with NEMA 1 Enclosure and no Thermostat

10" Flanged Immersion Heaters with NEMA 1 Enclosure and no Thermostat

12" Flanged Immersion Heaters with NEMA 1 Enclosure and no Thermostat

14" Flanged Immersion Heaters with NEMA 1 Enclosure and no Thermostat

Electric Flanged Immersion Heaters

Industrial flange immersion heaters provide heating solutions for fluid freeze protection and winterizing, hot or warm water storage, rinse tank heating, process chemical reactors, water-glycol heating, parts cleaning, plating and finishing chemicals, waste oil, wash systems and numerous other thermal heating applications.Typical heating mediums include:

- Process air

- Heat transfer oils

- Clean water

- Process water

- Lube and fuel oils

- Mild and corrosive solutions

- Wax and molasses

Contact Durex Industries for Industrial Flange Heaters

Durex Industries designs and manufactures electric flange immersion heaters, as well as other high-quality electric industrial heaters, temperature sensors, controls, and process systems. With decades of engineering experience, we can find the perfect industrial flange heater solution for your application.

- Specs & Options

- How to Order

- Application Guidelines

- Typical Applications

- Case Studies

- Literature Downloads

Flange Immersion Specs & Options

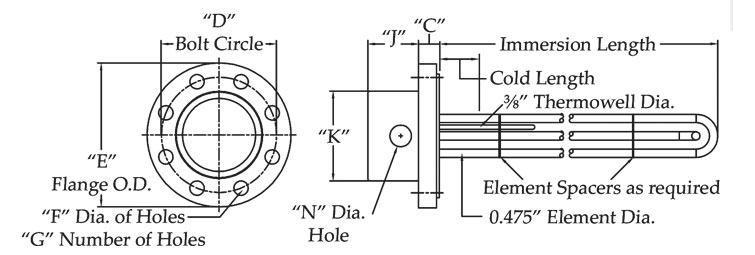

Back to TopHeater Specifications

| ANSI Flange Size | Enclosure Type | Typical Number of Elements | Heater Cold Length | C Flange Thickness |

D Bolt Circle Dia. |

E Flange Outer Dia. |

F Bolt Hole Dia. |

G Nr. of Bolt Holes |

J Enclosure Height |

K Enclosure Diameter |

L Enclosure Outer Dia. |

N Hole or NPT Size |

| 3" | NEMA 1 | 3 | 4" | 0.938" | 6" | 7.5" | 0.75" | 4 | 4" | 5.5" | N/A | 1" |

| NEMA 4 | 3 | 4" | 0.938" | 6" | 7.5" | 0.75" | 4 | 6" | 5.5" | 7" | 1" | |

| NEMA 7 | 3 | 4" | 0.938" | 6" | 7.5" | 0.75" | 4 | 6" | 5.5" | 7" | 1" | |

| NEMA 1 w/ Thermostat | 3 | 4" | 0.938" | 6" | 7.5" | 0.75" | 4 | 4" | 5.5" | N/A | 1" | |

| NEMA 4 w/ Thermostat | 3 | 4" | 0.938" | 6" | 7.5" | 0.75" | 4 | 6" | 5.5" | 7" | 1" | |

| Nema 7 w/ Thermostat | 3 | 4" | 0.938" | 6" | 7.5" | 0.75" | 4 | 6" | 5.5" | 7" | 1" | |

| 4" | NEMA 1 | 6 | 4" | 0.938" | 7.5" | 9" | 0.75" | 8 | 4" | 5.5" | N/A | 1" |

| NEMA 4 | 6 | 4" | 0.938" | 7.5" | 9" | 0.75" | 8 | 6" | 5.5" | 8" | 1" | |

| NEMA 7 | 6 | 4" | 0.938" | 7.5" | 9" | 0.75" | 8 | 6" | 5.5" | 8" | 1" | |

| 5" | NEMA 1 | 6/9 | 4" | 0.938" | 8.5" | 10" | 0.88" | 8 | 4" | 6.5" | N/A | 1" |

| NEMA 4 | 6/9 | 4" | 0.938" | 8.5" | 10" | 0.88" | 8 | 6" | 6.5" | 9" | 1" | |

| NEMA 7 | 6/9 | 4" | 0.938" | 8.5" | 10" | 0.88" | 8 | 6" | 6.5" | 9" | 1" | |

| 6" | NEMA 1 | 12/15 | 4" | 1" | 9.5" | 11" | 0.88" | 8 | 4" | 7.63" | N/A | 1 1/8" |

| NEMA 4 | 12/15 | 4" | 1" | 9.5" | 11" | 0.88" | 8 | 6" | 7.63" | 10" | 1 1/2" | |

| NEMA 7 | 12/15 | 4" | 1" | 9.5" | 11" | 0.88" | 8 | 6" | 7.63" | 10" | 1 1/2" | |

| 8" | NEMA 1 | 18/24 | 6" | 1.125" | 11.75" | 13.5" | 0.88" | 8 | 6" | 9.63" | N/A | 1 1/8" |

| NEMA 4 | 18/24 | 6" | 1.125" | 11.75" | 13.5" | 0.88" | 8 | 6" | 9.63" | 11.5" | 1 1/2" | |

| NEMA 7 | 18/24 | 6" | 1.125" | 11.75" | 13.5" | 0.88" | 8 | 6" | 9.63" | 11.5" | 1 1/2" | |

| 10" | NEMA 1 | 27/36 | 6" | 1.188" | 14.25" | 16" | 1" | 12 | 6" | 11.63" | N/A | 1 1/8" |

| NEMA 4 | 27/36 | 6" | 1.188" | 14.25" | 16" | 1" | 12 | 7" | 11.63" | 13.5" | 1 1/2" | |

| NEMA 7 | 27/36 | 6" | 1.188" | 14.25" | 16" | 1" | 12 | 7" | 11.63" | 13.5" | 1 1/2" | |

| 12" | NEMA 1 | 36/45 | 6" | 1.25" | 17" | 19" | 1" | 12 | 6" | 13.75" | N/A | 1 1/8" |

| NEMA 4 | 36/45 | 6" | 1.25" | 17" | 19" | 1" | 12 | 7" | 13.75" | 15.75" | 1 1/2" | |

| NEMA 7 | 36/45 | 6" | 1.25" | 17" | 19" | 1" | 12 | 7" | 13.75" | 15.75" | 1 1/2" | |

| 14" | NEMA 1 | 45/54 | 6" | 1.325" | 18.75" | 21" | 1.125" | 12 | 6" | 15.75" | N/A | 1 1/8" |

| NEMA 4 | 45/54 | 6" | 1.325" | 18.75" | 21" | 1.125" | 12 | 7" | 15.75" | 17.75" | 1 1/2" | |

| NEMA 7 | 45/54 | 6" | 1.325" | 18.75" | 21" | 1.125" | 12 | 7" | 15.75" | 17.75" | 1 1/2" |

Electrical and Physical Tolerances

| Maximum Voltage | 600VAC |

| Wattage Tolerance | +5% -10% |

| Resistance Tolerance | +10% -5% |

| Immersion Length Tolerance | ±1%; ±3/8" (±10mm) minimum |

Flange Immersion Heater Terminal Enclosures

Terminal enclosures (also called housings or boxes) protect the electrical terminals, bussing and connections. Durex offers a wide variety of enclosure options to meet just about every need. Note for hazardous location area applications: please ensure that complete /NFPA Class, Division, Gas Group, and T Code or other hazloc information is provided along with heater application details such as operating temperatures, pressures, etc.

Temperature Control & Sensing Options

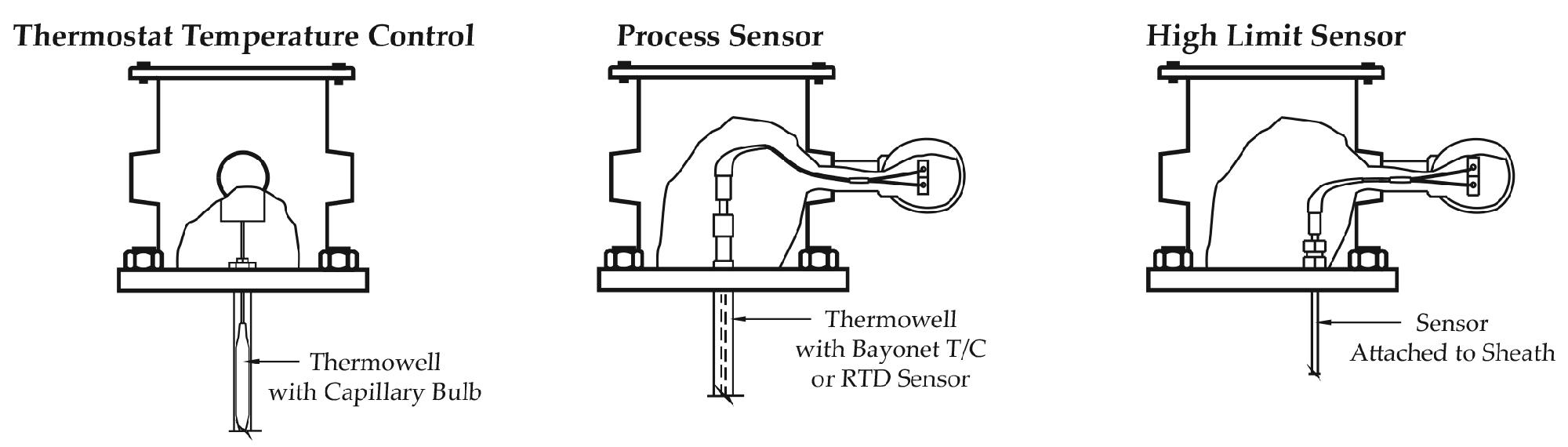

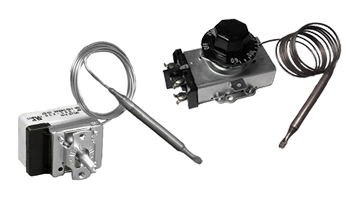

Flange Immersion Heaters With Thermostats

Flange Immersion Heaters With Thermostats

Thermostats can be mounted inside of the terminal enclosure to provide inexpensive, local temperature control of the flanged immersion heater and liquid being heated. Process (automatic control) and high limit (manual reset) thermostats are available. Temperature settings are adjustable unless a fixed set point thermostat is ordered. Single pole (SPST) thermostats are typically used for single phase immersion heaters and double pole (DPST) thermostats for three phase immersion heaters. For high current draw heaters, the thermostats are often wired for "pilot duty" to a user supplied relay. When ordering, please specify temperature range, the number of poles, the type of thermostat (process or high limit with manual reset), and if it will be used directly or wired for pilot duty.

Standard Available Bulb & Capillary Thermostats

| Temperature Range | Type | Max. Amps to 240VAC | Max. Amps at 480V | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 - 100°F | Single Pole (SPST) | 20 Amps | N/A | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 85 - 230°F | Single Pole (SPST) | 20 Amps | N/A | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120 - 570°F | Single Pole (SPST) | 20 Amps | N/A | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 - 100°F | Double Pole (DPST) | 30 Amps | 21 Amps | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 - 250°F | Double Pole (DPST) | 30 Amps | 21 Amps | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 - 550°F | Double Pole (DPST) | 30 Amps | 21 Amps |

Flange Immersion Heaters With Temperature Sensors

Process Temperature Sensors - A thermocouple or RTD sensor probe can be inserted into a thermowell in the heater to measure process fluid temperature. Type J and Type K are the most common thermocouple calibrations, while a Pt 100 Ohm DIN Curve sensor is the most common RTD used. Type J thermocouples and RTDs are typically used to 1000°F (540°C), whereas Type K thermocouples are used to 2000°F (1100°C) max. Other sensors are available. Standard lead length is 72" (1825mm). Specify sensor type and lead length when ordering.

High Limit Temperature Sensors - A thermocouple or RTD sensor probe is mounted via compression fitting into the heater flange and clamped directly to a heater element to measure element temperature. This allows monitoring of the sheath to prevent over temperature conditions that may shorten heater life and/or prevent fluid degradation. If the heater will be used vertically or in a circulation heater, contact Durex to ensure the correct sensor placement.

Standard lead length is 72" (1825mm). When ordering, specify sensor type, sensor mounting style and lead length.

Flanged immersion heaters allow for both process and high limit temperature sensors.

Flanged Immersion Heaters with Temperature Control Panels

Durex Industries electrical temperature control panels meet a wide variety of industrial requirements by providing an extensive line of standard and custom engineered solutions. All temperature control panels are fully pre-wired and tested at the factory and come with a set of drawings including schematics and installation and maintenance manuals. Standard temperature control panels include NEMA 12 enclosure, main power disconnect, process temperature controller, pilot lights, panel labels, primary and secondary fusing, and ventilation fan /filter (if required). Other options available.

Durex Industries electrical temperature control panels meet a wide variety of industrial requirements by providing an extensive line of standard and custom engineered solutions. All temperature control panels are fully pre-wired and tested at the factory and come with a set of drawings including schematics and installation and maintenance manuals. Standard temperature control panels include NEMA 12 enclosure, main power disconnect, process temperature controller, pilot lights, panel labels, primary and secondary fusing, and ventilation fan /filter (if required). Other options available.Immersion Heater Construction Options

Voltage and Power Rating - A large variety of industry standard designed heaters are available for quick ship. However, custom volts, watts and watt density designs are available upon request.

Flange Sizes and Ratings - ANSI Class 150 flanges are available standard from 3”to 14”. Smaller sizes such as 2” and 2 ½”, as well as, larger sizes up to 40” can be provided. Class 300 and Class 600 flanges can be supplied with minimal lead time effect; up to Class 2500 are also available. DN European metric type flanges are also available from DN80 to DN1000 sizes and pressure ratings from PN6 to PN40.

Plate Flanges - Plate flanges are typically custom fabricated to fit in smaller equipment that may have lower pressure or non-standard size requirements. As these are typically unique to a piece of equipment, complete plate flange details (length, width, thickness, holes, material, etc.) must be provided to ensure proper fit and function.

Flange Materials - Steel and 304SS flange materials are standard. Also available are 316SS, Inconel® 600 and other alloys upon request. Consult Durex for availability.

Sheath Materials - Copper, steel, 304SS, 316SS and Incoloy® 840 materials are standard. Also available are Incoloy® 800, 321SS, Inconel® 600, etc. Seamless and heavy wall construction for higher pressure and/or corrosive fluids can be provided as well for extended heater life.

Immersion Length and Cold Length - For simplicity and quicker delivery, it is recommended to use standard design immersion lengths and cold (unheated) lengths on our catalog heaters. However, heater element immersion length, as well as the cold length, can be varied to suit application requirements. For example, longer cold lengths are often used to keep the termination area cool or focus heat generation in a specific area of the media being heated.

Sheath Treatment and Finish - Passivation treatment is available to remove free iron from the heater sheath. Electropolishing to chemically mill the exterior surface to a low Ra finish is also available. Contact Durex for details.

Electrical Terminal Enclosures

NEMA 1 General purpose terminal enclosures are standard. Options include:

- General Purpose (NEMA 1)

- Moisture Resistant (NEMA 4)

- Moisture and Corrosion Resistant (NEMA 4X)

- Explosion Resistant (NEMA 7) Class 1 Division 1 Gas Groups B, C and D

- Explosion and Moisture Resistant (NEMA 4/7) Class 1 Division 1 Gas Groups B, C and D

- Explosion, Moisture, Corrosion Resistant (NEMA 4X/7) Class 1 Division 1 Gas Groups B, C and D

Electrical Terminal Enclosures

Notes on Hazardous Location (Hazloc) Installations

To ensure proper terminal enclosure application, please provide the following information to ensure proper enclosure selection and heater rating:

- The maximum working pressure and temperature of the heating application

- The medium being heated

- The heater mounting orientation – horizontal or vertical

- The specific hazloc area designation (Class (or Zone), Division, Gas Group)

- The specific hazloc T Code (temperature code) designation

- The maximum expected ambient temperature of the installation

Class 1 Division 1 (Zone 1) Location Installations: NRTL (Nationally Recognized Testing Laboratory) Certified enclosures ensure explosion resistant integrity of the heater in the application.

Class 1 Division 2 (Zone 2) Location Installations: Class 1 Division 1 (NEMA 7) rated enclosures are required when thermostats are employed. However, per NEC/NFPA 70, the use of a general purpose enclosure (such as a NEMA 4 enclosure) is acceptable if no thermostat or other arcing device is present in the terminal enclosure and the enclosure and all internal components will remain below the designated T Code temperature for the hazloc area during operation.

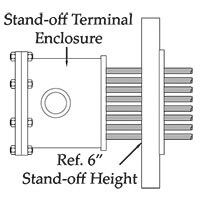

Stand-Off Terminal Enclosures -The electrical enclosure is separated from the flange by a six inch air gap to lower the ambient temperature of the electrical wiring in the enclosure. This option is recommended whenever the flange temperature is expected to exceed 400°F (200°C).

Stand-Off Terminal Enclosures -The electrical enclosure is separated from the flange by a six inch air gap to lower the ambient temperature of the electrical wiring in the enclosure. This option is recommended whenever the flange temperature is expected to exceed 400°F (200°C).

ASME Code Stamp & CRN Certification - For higher pressure and/or temperature applications, Durex can provide ASME Section VIII, Div. 1 U-part stamped flange immersion heaters including National Board Registration as required. We can also obtain Canadian Registration Numbers (CRN) for Canadian Province requirements. Please provide flange size, rating and material, the max operating temperature and pressure, design pressure and temperature, MDMT value, corrosion allowance and gasket specifications.

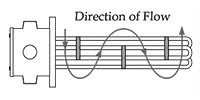

Flow Baffles - For circulation applications, flow baffles are employed to induce cross flow over the heater elements thereby improving heat transfer from the heater elements to the flowing fluid. However, the tradeoff is increased pressure drop across the circulation heater. Contact Durex for more information and design assistance.

Flow Baffles - For circulation applications, flow baffles are employed to induce cross flow over the heater elements thereby improving heat transfer from the heater elements to the flowing fluid. However, the tradeoff is increased pressure drop across the circulation heater. Contact Durex for more information and design assistance.

Paint & Coatings - Steel flanges and enclosures are primer painted as standard. Stainless steel and other alloy flanges and enclosures are not painted, unless specifically requested. Paint on primer is also an available option.

Seal Options

Silicone Conformal Coating – Standard on catalog units, this seal provides general moisture / contamination protection to 220°F (105°C). However, it is porous and will allow moisture penetration over time. Not recommended for storage or use in high humidity environments.

Silicone RTV – Offers improved moisture and contamination protection to 400°F (200°C). However, it is also porous and will allow moisture ingress over time.

Epoxy Seal – Offers the best moisture and contamination protection of these seal choices. Rated for 450°F (230°C), this seal has low porosity and is recommended for higher temperature applications, high moisture environments and where long term storage is foreseen.

Flange Immersion How to Order

Back to TopTo place an order, or get a quotation, please provide the information itemized below. Contact Durex Industries for further assistance.

- Quantity

- Type of Medium Being Heated

- Tank or Vessel Size

- Insulated or Uninsulated Tank

- Required Temperatures

- Electrical Rating - Voltage, phase, Wattage

- Flange Size, Rating Material - ANSI flange size, pressure rating and material, or plate flange dimensions and material

- Element Sheath Material - Copper, Steel, 304SS, 316SS, Incoloy® 840, Incoloy® 800 or other

- Number of Heater Elements - Provide number of heater elements (and element diameter if other than 0.475” standard)

- Element Watt Density - 8, 16, 23, 48 or 60 W/in2, or other watt density value

- Immersion and Cold Lengths - Provide desired immersion length or max. allowable length, and cold length if non-standard.

- Seal Options - Silicone conformal coating (standard), RTV or epoxy.

- Electrical Enclosure - General purpose (NEMA 1) is standard, moisture resistant (NEMA 4) or other hazardous location rated enclosure (see Electrical Terminal Enclosures for specific requirements)

- Sensing & Control - None (standard), thermostat type (process or high limit) and temperature range, or sensor type and details (process or high limit sensor and what type thermocouple or RTD.

Flange Immersion Application Guidelines

Back to TopThe goal is to optimize the heater configuration to ensure the longest life possible, while minimizing overall product and life cycle costs. The general temperature, sheath material and watt density guidelines below can aid in proper heater selection for some common liquids. Contact Durex for further assistance.

| Liquid | Max. Operating Temps °F (°C) | pH Level and/or Concentration | Recommended Sheath Material | Typical Flange Material | Max. Watt Density W/in2(W/cm2) |

| Clean, Potable Water | 212 (100) | Neutral (pH 6 to 8) | Copper | Brass | 60-90 (9.5-14) |

| Process Water & Weak Solution | 212 (100) | pH 5 to 9; 2-3% | Incoloy®, 304SS | Steel or 304SS | 48 (7.5) |

| Demineralized, Deionized Water | 212 (100) | Neutral | 304SS or 316SS (passivated) | 304SS or 316SS | 60 (9.5) |

| Weak (Acidic) Solutions* | 210 (100) | Up to 5-6% | Incoloy®, 316SS | Steel | 48 (7.5) |

| Mildly Corrosive (Acidic) Solutions* | 180 (80) | 5-15% | Incoloy®, 316SS | 304SS or 316SS | 20-30 (3.5) |

| Severely Corrosive (Acidic) Solutions* | 180 (80) | >15% | Incoloy®, titanium, Teflon® | 304SS or other | 15-16 (2.5) |

| Caustic Soda 10% | 200 (100) | pH 14; 10% | Incoloy® | Steel | 20-23 (3.5) |

| Caustic Soda 50% | 250 (120) | pH 14; 50% | Incoloy® | Steel | 16 (2.5) |

| Fuel Oil 1 & 2; Kerosene Lube Oil SAE 10 to 30 | 200-250 (95-120) | - | Steel | Steel | 20-23 (3.5) |

| Fuel Oil 4 & 5; Lube Oil SAE 40 to 50 | 200-250 (95-120) | - | Steel | Steel | 15-16 (2.5) |

| Fuel Oil 6 & Bunker C | 160 (70) | - | Steel | Steel | 6-8 (1.2) |

| Hydraulic Oil | 100 (40) | - | Steel | Steel | 15-16 (2.5) |

| Ethylene Glycol | 300 (150) | - | Steel | Steel | 23-30 (3.5-4.5) |

| Glycerin | 500 (260) | - | Incoloy® | Steel | 8-10 (1.5) |

| Molten Salt Bath | 800 (425) | - | Steel, 321SS, Monel® | Steel | 23-30 (3.5-4.5) |

| Paraffin Wax | 150 (65) | - | Steel or 304SS | Steel | 15-16 (2.5) |

| Molasses | 100 (40) | - | 304SS or 316SS | 304SS | 4-5 (0.7) |

* Sheath material and watt density dependent on type of acid, concentration, temperature, aeration, movement, etc.

- Please note that the user accepts full responsibility for validating that a heater is suitable for a given liquid or gas heating application.

- Ensure that heater elements are completely covered in liquid AT ALL TIMES. Failure to do so may cause the heater elements to operate in open air and fail prematurely, or worse, lead to ignition of flammable vapor mixtures, causing serious personal injury and equipment damage. Liquid level sensors are highly recommended.

- Durex recommends the use of a thermostat or process controller as well as a high limit sensor and FM approved safety controller to prevent unexpected over temperature conditions.

Flange Immersion Typical Applications

Back to Top- Process Air & Gases

- Process Chemical Reactors

- Boilers and Water Heating

- Rinse Tank Heating

- Parts Cleaning Solutions

- Lube Oil & Fuel Oil Heating

- Hydraulic and Heat Transfer Oils

- Storage Tanks

- Caustic Solution Heating

- Plating & Finishing Chemicals

- Water-Glycol Solution Heating

- Fluid Freeze Protection & Winterizing

- Waste Oil

- Molten Salt Bath Heating

Flange Immersion Case Studies

Back to TopImmersion Heaters for Lubrication Oil Tanks

Flange Immersion Literature Downloads

Back to TopProcess Heater Brochure PROC-BROC-0912 - 7MB

ASME Section VIII Division 1 Certificate - 61KB

National Board "R" Stamp Repair Certificate

Installation & Operations Manual - Flange Immersion Heaters - 351KB