Industrial Screw Plug Immersion Heaters

Screw plug immersion heaters provide heating solutions for fluid freeze protection and winterizing, hot or warm water storage, parts cleaning, plating and finishing chemicals, waste oil, wash systems and numerous other thermal heating applications.

Custom or Industry Standard Screw Plug Heaters

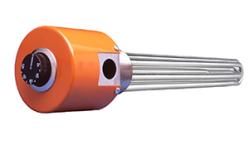

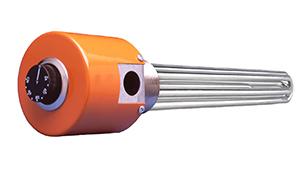

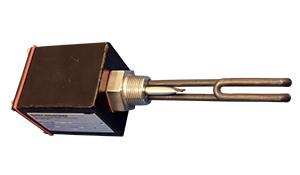

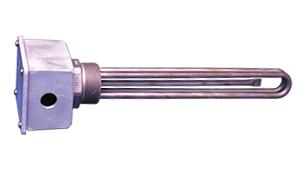

Durex industrial screw plug immersion heaters are constructed of hairpin bent tubular heating elements brazed or welded into threaded screw plugs. These heating elements are inserted through a threaded hole or through a threaded coupling attached to a tank or vessel for direct heating of liquids. Electrical enclosures are used to protect the heater terminals, especially around moisture and corrosive areas. Thermostats, temperature sensors or temperature control panels deliver precise temperature control to your thermal heating application.

Plug Immersion Heater Design Features:

- Custom or industry standard designs

- NPT screw plug sizes: 1", 1.25”, 1.50”, 2”, 2.5”, 3”, 4”

- NPT screw plug materials: Steel, brass, 304 & 316 stainless steel

- Element materials: Steel, copper, incoloy® 800 & 840, 304 & 316 stainless steel

- C-UL recognized heater elements available

- Rating up to 600 volts

- NEMA 1, NEMA 4 light duty, NEMA 4 heavy duty, and other enclosures available

- Integral thermostats, thermocouples or control panels for temperature control and sensing

Electric Screw Plug Immersion Heaters

Durex Industries manufactures electric screw plug immersion heaters for industrial and process heating applications, providing economical and reliable heating for a large variety of tanks or vessels. Typical heating mediums include:

- Clean water

- Process water

- Lube and fuel oils

- Mild and severely corrosive solutions

- Hydraulic oil and ethylene glycol

Hundreds of Industry Standard Screw Plug Designs

Contact Durex Industries for Electric Screw Plug Immersion Heaters

Durex has over 40 years of experience with custom designed & engineered electric immersion heaters. Our engineers can assist you in providing the best and most efficient heating solution for your application requirements.

- Specs & Options

- How to Order

- Application Guidelines

- Typical Applications

- Case Studies

- Literature Downloads

Screw Plug Immersion Specs & Options

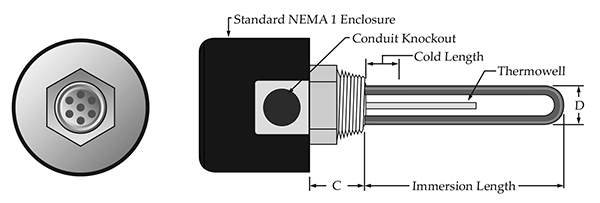

Back to TopPlug Orientation with Thermowell

Plug Immersion Heater Specifications

| Plug NPT Size | "C" | Min. Insertion Hole Dia. "D" | Min. Unheated (Cold) Length | Element Diameter | Thermowell Max T-Stat Bulb or Sensor Dia. | Number of Elements | Max. Voltage |

| 1" | 1.25" (32mm) | 1 1/8" (29mm) | 1" (25mm) | 0.315" (8mm) | 1/4" (6.4mm) | 1 | 480 |

| 1 1/4" | 1.25" (32mm) |

1 3/8" (35mm) | 1" (25mm) | 0.315" (8mm) | 1/4" (6.4mm) | 1 or 2 | 480 |

| 1 1/2" | 1.46" (37mm) | 1 1/2" (38mm) | 1.5" (38mm) | 0.375" (9.525mm) | 3/8" (9.5mm) | 2 or 3 | 480 |

| 2" | 1.88" (48mm) | 2" (50.8mm) | 2" (50.8mm) | 0.475" (12mm) | 3/8" (9.5mm) | 2 or 3 | 600 |

| 2 1/2" | 2" (51mm) | 2" (50.8mm) | 2" (50.8mm) | 0.475" (12mm) | 3/8" (9.5mm) | 3 | 600 |

| 3" | 2.2" (55.6mm) | 2" (50.8mm) | 2" (50.8mm) | 0.475" (12mm) | 3/8" (9.5mm) | 3 | 600 |

| 4" | 2.2" (55.6mm) | 2" (50.8mm) | 2" (50.8mm) | 0.475" (12mm) | 3/8" (9.5mm) | 3 or 6 | 600 |

Wattage Tolerance All Units +5% -10%; Resistance Tolerance All Units +10% -5%

Immersion Length Tolerance All Units: +0 -1/2" (+0 -13mm) or +0 -1%, whichever is greater

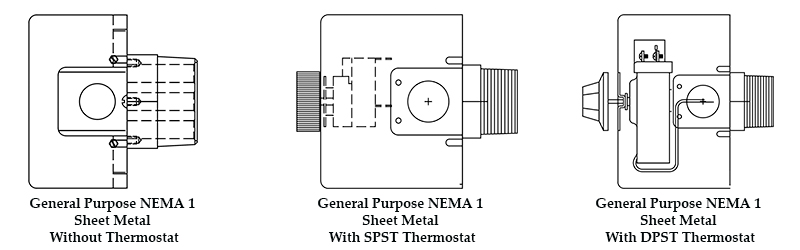

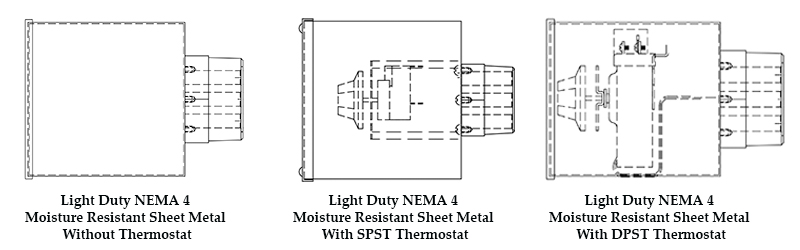

Terminal Enclosure Options for Screw Plug Immersion Heaters

Terminal enclosures (also called housings or boxes) protect the electrical terminals, bussing and connections. Durex offers a wide variety of enclosure options to meet just about every need. Note for hazardous location area applications: please ensure that complete /NFPA Class, Division, Gas Group, and T Code or other hazloc information is provided along with heater application details such as operating temperatures, pressures, etc.

General Purpose NEMA 1 - Sheet Metal Terminal Enclosures

Light Duty NEMA 4 - Moisture Resistant Sheet Metal Terminal Enclosures

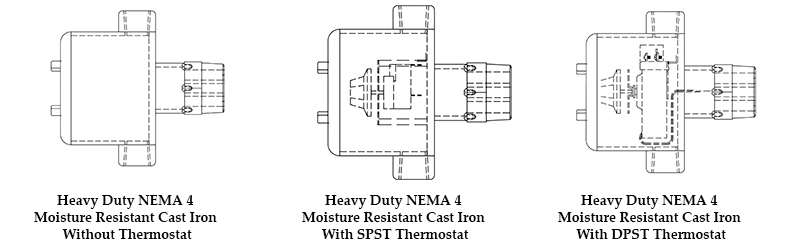

Heavy Duty NEMA 4 - Moisture Resistant Cast Iron Terminal Enclosures

Temperature Control & Sensing Options

Screw Plug Immersion Heaters With Thermostats

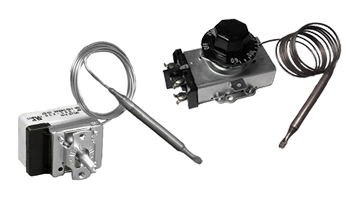

Thermostats can be mounted inside of the terminal enclosure to provide inexpensive, local temperature control of the screw plug immersion heater and liquid being heated. Process (automatic control) and high limit (manual reset) thermostats are available. Temperature settings are adjustable unless a fixed set point thermostat is ordered. Single pole (SPST) thermostats are typically used for single phase immersion heaters and double pole (DPST) thermostats for three phase immersion heaters. For high current draw heaters, the thermostats are often wired for "pilot duty" to a user-supplied relay. When ordering, please specify temperature range, the number of poles, the type of thermostat (process or manual reset, high limit), and if it will be used directly or wired for pilot duty.

Thermostats can be mounted inside of the terminal enclosure to provide inexpensive, local temperature control of the screw plug immersion heater and liquid being heated. Process (automatic control) and high limit (manual reset) thermostats are available. Temperature settings are adjustable unless a fixed set point thermostat is ordered. Single pole (SPST) thermostats are typically used for single phase immersion heaters and double pole (DPST) thermostats for three phase immersion heaters. For high current draw heaters, the thermostats are often wired for "pilot duty" to a user-supplied relay. When ordering, please specify temperature range, the number of poles, the type of thermostat (process or manual reset, high limit), and if it will be used directly or wired for pilot duty.

Standard available bulb & capillary thermostats

| Temperature Range | Type | Max. Amps to 240VAC | Max. Amps at 480v |

| 0 - 100°F | Single Pole (SPST) | 20 Amps | N/A |

| 85 - 230°F | Single Pole (SPST) | 20 Amps | N/A |

| 120 - 570°F | Single Pole (SPST) | 20 Amps | N/A |

| 0 - 100°F | Double Pole (DPST) | 30 Amps | 21 Amps |

| 60 - 250°F | Double Pole (DPST) | 30 Amps | 21 Amps |

| 100 - 550°F | Double Pole (DPST) | 30 Amps | 21 Amps |

Screw Plug Immersion Heaters With Temperature Sensors

Process Temperature Sensors

A thermocouple or RTD sensor probe can be inserted into a thermowell in the heater to measure process fluid temperature. Type J and Type K are the most common thermocouple calibrations, while 100 Ohm and 1000 Ohm are the most common RTD probes used. Type J thermocouples and RTDs are typically used to 1000°F (540°C), whereas Type K thermocouples are used to 2000°F (1100°C) max. Other sensor types are available. Standard lead length is 60" (1825mm). Specify sensor type and lead length when ordering.

High Limit Temperature Sensors

A thermocouple or RTD sensor probe is fed through the screw plug and clamped directly to a heater element to measure element temperature. This allows monitoring of the sheath temperature to prevent over temperature conditions that may shorten heater life and/or prevent fluid degradation. As an option, the high limit sensor can be inserted into a thermowell clamped or welded to the heater element sheath. This facilitates easy sensor replacement, but at the expense of a slower sensor response time. If the heater will be used vertically or in a circulation heater, contact Durex to ensure the correct sensor placement. Standard lead length is 60" (1825mm). When ordering, specify sensor type, sensor mounting style and lead length.

2.5", 3" & 4" screw plug heaters allow for both process and high limit temperature sensors.

Screw Plug Heaters With Temperature Control Panels

Durex Industries electrical temperature control panels meet a wide variety of industrial requirements by providing an extensive line of standard and custom engineered solutions. All temperature control panels are fully pre-wired and tested at the factory and come with a set of drawings including schematics and installation and maintenance manuals. Standard temperature control panels include NEMA 12 enclosure, main power disconnect, process temperature controller, pilot lights, panel labels, primary and secondary fusing, and ventilation fan /filter (if required). Other options available.

Durex Industries electrical temperature control panels meet a wide variety of industrial requirements by providing an extensive line of standard and custom engineered solutions. All temperature control panels are fully pre-wired and tested at the factory and come with a set of drawings including schematics and installation and maintenance manuals. Standard temperature control panels include NEMA 12 enclosure, main power disconnect, process temperature controller, pilot lights, panel labels, primary and secondary fusing, and ventilation fan /filter (if required). Other options available.

Plug Immersion Heater Construction Options

Screw Plug Sizes - 1", 1.25", 1.50", 2", 2.50", 3", 4" NPT (National Pipe Thread). Other pipe thread sizes and thread types (e.g. British Standard Pipe or BSP) are available upon request. Screw plug materials available are brass, steel, 304 and 316 stainless steels. Others are possible upon request.

Voltage & Power Ratings - A large variety of industry standard designed heaters are available for quick ship. However, custom volts, watts and watt density designs are available upon request.

Cold Length - The unheated (cold) length can be varied to suit application requirements. Longer unheated sections are often used to keep the termination area cool or to focus heat generation in a specific area of the media being heated.

Sheath Treatment & Finish - For pharmaceutical and other "clean" applications, a bright anneal finish can be supplied. Also available, depending on configuration, are passivation and electropolishing, which remove any free iron and also provides a smoother surface finish both on the heater element as well as the screw plug fitting.

Seal Options

Silicone Conformal Coating - Standard on catalog units, this seal provides general moisture / contamination protection to 220°F (105°C). However, it is porous and will allow moisture penetration over time. Not recommended for storage or use in high humidity environments.

Silicone RTV - Offers improved moisture and contamination protection to 400°F (200°C). However, it is also porous and will allow moisture ingress over time.

Epoxy Seal - Offers the best moisture and contamination protection of these seal choices. Rated for 450°F (230°C), this seal has low porosity and is recommended for higher temperature applications, high moisture environments and where long-term storage is foreseen.

Screw Plug Immersion How to Order

Back to TopContact Durex Industries for further assistance.

- Quantity

- Type of Medium Being Heated

- Tank or Vessel Size

- Insulated or Uninsulated Tank

- Required Temperatures

- Electrical Rating: Voltage, phase, Wattage

- Screw Plug Size: 1", 1.25", 1.50", 2", 2.50", 3", 4" NPT or other size

- Plug Material: Standard; brass, steel, 304SS or 316SS

- Element Sheath Material: Copper, Steel, 304SS, 316SS, Incoloy® or other

- Element Diameter: 0.315”(8mm), 0.375”(9.525mm), 0.475”(12mm), or other

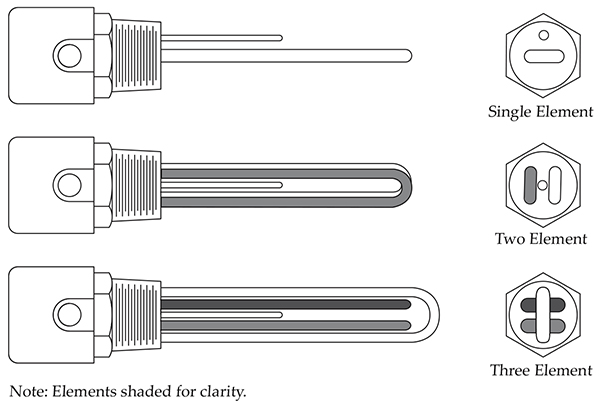

- Element Quantity: One, two, three, or other

- Element Watt Density: 8, 16, 23, 48 or 60 W/in2, or other watt density value

- Immersion Length: Provide desired immersion length or maximum length allowable.

- Seal Options: Silicone conformal coating (standard), RTV or epoxy

- Electrical Enclosure: NEMA 1(standard), NEMA 4, NEMA 7, NEMA 4/7 or other; If a hazardous location rating required, please designate location classification.

- Temperature Control: None (standard), process (automatic control) or high limit (manual reset) thermostats

- Temperature Sensor: None (standard), process sensor type or/and high limit sensor type and required lead length

- Temperature Control Panel

Screw Plug Immersion Application Guidelines

Back to TopThe goal is to optimize the immersion heater configuration to ensure the longest life possible, while minimizing overall product and life cycle costs. The general temperature, sheath material and watt density guidelines below can aid in proper heater selection for some common liquids. Contact Durex for further assistance.

| Liquid | Max. Operating Temps °F (°C) | pH Level and/or Concentration | Recommended Sheath Material | Typical Plug Material | Max. Watt Density W/in2(W/cm2) |

| Clean, Potable Water | 212 (100) | Neutral (pH 6 to 8) | Copper | Brass | 60-90 (9.5-14) |

| Process Water & Weak Solution | 212 (100) | pH 5 to 9; 2-3% | Incoloy®, 304SS | Steel or 304SS | 48 (7.5) |

| Demineralized, Deionized Water | 212 (100) | Neutral | 304SS or 316SS (passivated) | 304SS or 316SS | 60 (9.5) |

| Weak (Acidic) Solutions* | 210 (100) | Up to 5-6% | Incoloy®, 316SS | Steel | 48 (7.5) |

| Mildly Corrosive (Acidic) Solutions* | 180 (80) | 5-15% | Incoloy®, 316SS | 304SS or 316SS | 20-30 (3.5) |

| Severely Corrosive (Acidic) Solutions* | 180 (80) | >15% | Incoloy®, titanium, Teflon® | 304SS or other | 15-16 (2.5) |

| Caustic Soda 10% | 200 (100) | pH 14; 10% | Incoloy® | Steel | 20-23 (3.5) |

| Caustic Soda 50% | 250 (120) | pH 14; 50% | Incoloy® | Steel | 16 (2.5) |

| Fuel Oil 1 & 2; Kerosene Lube Oil SAE 10 to 30 | 200-250 (95-120) | - | Steel | Steel | 20-23 (3.5) |

| Fuel Oil 4 & 5; Lube Oil SAE 40 to 50 | 200-250 (95-120) | - | Steel | Steel | 15-16 (2.5) |

| Fuel Oil 6 & Bunker C | 160 (70) | - | Steel | Steel | 6-8 (1.2) |

| Hydraulic Oil | 100 (40) | - | Steel | Steel | 15-16 (2.5) |

| Ethylene Glycol | 300 (150) | - | Steel | Steel | 23-30 (3.5-4.5) |

| Glycerine | 500 (260) | - | Incoloy® | Steel | 8-10 (1.5) |

| Molten Salt Bath | 800 (425) | - | Steel, 321SS, Monel® | Steel | 23-30 (3.5-4.5) |

| Paraffin Wax | 150 (65) | - | Steel or 304SS | Steel | 15-16 (2.5) |

| Molasses | 100 (40) | - | 304SS or 316SS | 304SS | 4-5 (0.7) |

* Sheath material and watt density dependent on type of acid, concentration, temperature, aeration, movement, etc.

- Please note that the user accepts full responsibility for validating that a heater is suitable for a given liquid or gas heating application.

- Ensure that heater elements are completely covered in liquid AT ALL TIMES. Failure to do so may cause the heater elements to operate in open air and fail prematurely, or worse, lead to ignition of flammable vapor mixtures, causing serious personal injury and equipment damage. Liquid level sensors are highly recommended.

- Durex recommends the use of a thermostat or process controller as well as a high limit sensor and FM approved safety controller to prevent unexpected over temperature conditions.

Screw Plug Immersion Typical Applications

Back to Top- Boilers & Water Heating

- Clean & Process Water

- Freeze Protection & Winterizing

- Heat Transfer Systems

- Lube & Fuel Oil Heating

- Parts Cleaning Solutions

- Plating & Finishing Chemicals

- Storage Tanks

- Temperature Control Units

- Wash Systems

- Wax Heating

- Waste Oil

- Molten Salt Bath Heating

Screw Plug Immersion Case Studies

Back to TopDiesel Fuel Tank Immersion Heaters for Generators

Electric Immersion Heaters for Parts Finishing Tanks

Immersion Heaters for Fuel Oil & Lube Oil Systems

Screw Plug Immersion Literature Downloads

Back to TopProcess Heater Brochure PROC-BROC-0912- 7MB

Installation & Operations Manual - Screw Plug Immersion Heaters - 650KB